April 1, 2021

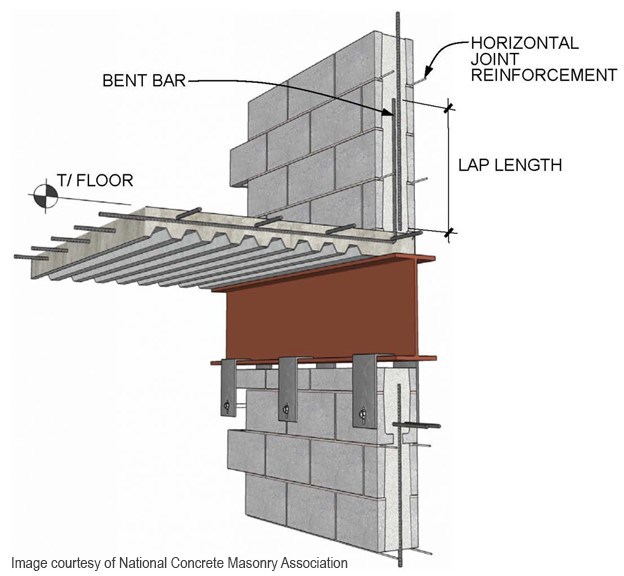

Hybrid masonry is a structural system that utilizes reinforced masonry walls within a steel framed structure. The reinforced masonry infill participates structurally with the frame and provides lateral strength and stiffness to the system. The concept of using masonry infills to resist lateral forces is not new, having been used successfully throughout the world in different forms. The novelty of the hybrid masonry design approach is in the connection detailing between the masonry and steel frame, which offers multiple alternative means of transferring loads into the masonry or isolating the masonry infill from the frame.

The main reason for the development of the hybrid system is to simplify and speed up construction. When properly detailed, this system allows a steel frame to be erected with temporary bracing and later infilled by CMU; this process eliminates conflicts and overlaps between the different trades involved.

There are three hybrid wall types, and the classification is dependent upon the degree of confinement of the masonry within the frame:

- Type I walls have soft joints (gaps that allow lateral drift at the columns or vertical deflection at the top) at the columns and the top of the wall. The framing supports the full weight of the masonry walls and other gravity loads

- Type II walls have soft joints at the columns and are built tight at the top of the wall. The walls are load bearing in addition to shear resisting elements

- Type III walls are built tight at the columns and the top of the wall

Odeh Engineers pioneered the use of this unique system in New England by proposing and designing a hybrid CMU/Steel shear core for the Hilton Garden Inn hotel in Brookline, MA. This allowed the steel frame structure to be built ahead of the masonry infills, which where constructed once the steel was frame was completed.

You can learn more about Hybrid CMU construction on the NCMA website.